Externally mounted agitators.

For Biogas & wastewater applications

For Biogas & wastewater applications

Dynamically Balance Propeller

Stainless Steel Construction

Variable adjustment up to +/- 30°

External Maintenance Items

Low-Noise Gear Design

Wall-mounted agitator with adjustment up to +/- 30°

Application: The Giantmix FR SP has been specially designed to optimise the biological process in digester and process tanks with almost constant substrate levels.

Installation Depth: Because of the unique SUMA-sealing system, the installation depth of 8 m beneath substrate level but full swivel range is possible. Deeper immersion depths on request.

Sealing System: The flexible tube feed through is sealed with 2 EPDM sealing membranes (inside and outside), ensuring no leaks.

Easy Maintenance: Almost all maintenance activities can be carried out from outside the tank, meaning less downtime, and less operator risk.

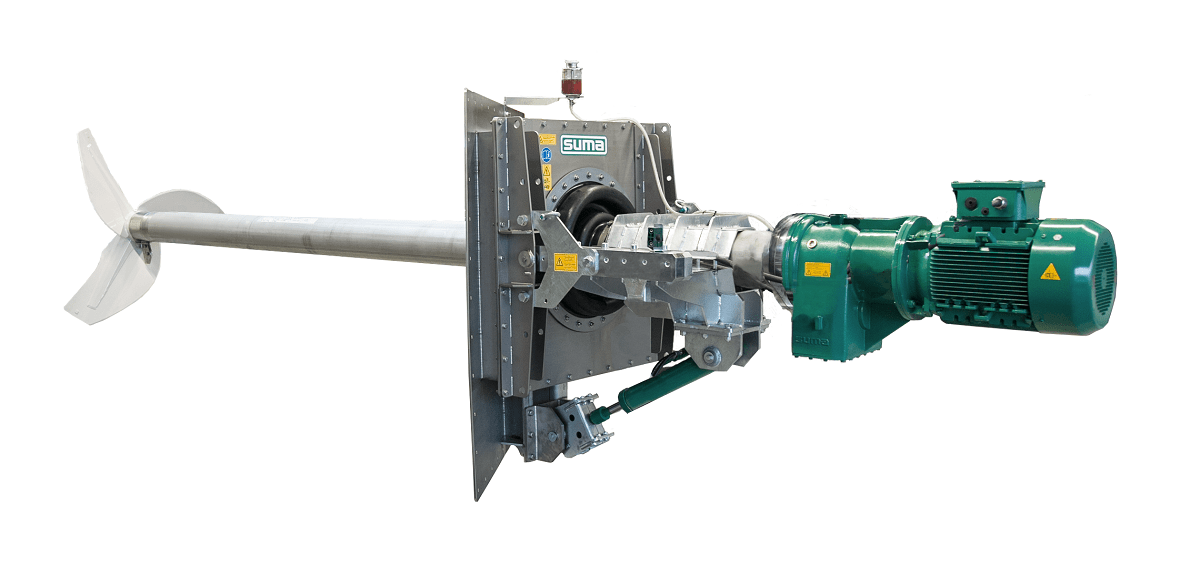

Giantmix FR SP

Vertically Adjustable: up to 30°

Horizontally Adjustment: +/- 25°

Submersion Depth: Suitable up to 8 m beneath substrate level. Deeper immersion depths on request

Electric Motor: 7.5 – 18.5 kW (50Hz)

Shaft Length: 3.0 – 4.0 m

Propeller: Ø620 – 800 mm

Propeller Speed: 200 – 400 RPM

Shaft + Sealing Plate Material: ss304 or ss316

Thermal Protection: PTC 160°C

Ex-Zone: 1 or 2

For optimised mixing in smaller tanks

Application: The Giantmix FR Light has been specially designed for agitation of smaller tanks.

Easy Maintenance: With an external drive motor and transmission, the Giantmix FR Light makes maintenance easy. No need for removing the agitator, or opening digestion tanks!

Giantmix FR Light

Submersion Depth: Suitable up to 6 m beneath liquid level

Electric Motor: 4.0 – 7.5 kW (50Hz)

Shaft Length: 1.0 / 1.5 m

Propeller: Ø520 – 700 mm

Propeller Speed: 180 – 380RPM

Shaft + Sealing Plate Material: ss304 or ss316

Thermal Protection: PTC 160°C

Ex-Zone: 2

Optimised mixing for almost constant liquid level

Application: The Giantmix FR has been specially designed to optimise the biological process in digester and process tanks with almost constant substrate levels.

Installation Depth: Installation of up to 1.5 m beneath liquid level. Deeper immersion depths on request.

Sealing System: Sealing membrane made of EPDM60 + bearing housing with mechanical seal of SiC/SiC.

Drive Transmission: Two-step spur gear for quiet operation

Easy Maintenance: Almost all maintenance activities can be carried out from outside the tank, meaning less downtime, and less operator risk.

Giantmix FR

Vertically Adjustable: up to +/-25° (Inclination adjustment by upper control arm, toothed rack with winch or hydraulic drive)

Submersion Depth: Suitable up to 1.5 m beneath substrate level. Deeper immersion depths on request

Electric Motor: 7.5 – 18.5 kW (50Hz)

Shaft Length: 3.0m

Propeller: Ø580 – 850 mm

Propeller Speed: 200 – 400 RPM

Shaft + Sealing Plate Material: ss304 or ss316

Thermal Protection: PTC 160°C

Ex-Zone: 1 or 2

Long-axis agitator with adjustment up to +/- 30°

Application: The Giantmix FT Long Axis agitator has been specially designed for large tank applications, with up to 6.0m shaft length.

Shaft Length: From 4.0-6.0m

Installation Depth: Because of the unique SUMA-sealing system, the installation depth of 8 m beneath substrate level but full swivel range is possible. Deeper immersion depths on request.

Sealing System: Membrane made of EPDM60 + SiC/SiC mechanical seal.

Drive Transmission: Helical teeth planetary gear, ensuring low noise operation.

Easy Maintenance: Almost all maintenance activities can be carried out from outside the tank, meaning less downtime, and less operator risk.

Giantmix FT Long-Axis

Vertically Adjustable: up to +/-30°

Horizontally Adjustable: +/- 30°

Submersion Depth: Suitable up to 8.0 m beneath liquid level. Deeper immersion depths on request

Electric Motor: 7.5 – 22.0 kW (50Hz)

Shaft Length: 4.0 – 6.0m

Propeller: Ø700 – 850 mm

Propeller Speed: 200 – 400 RPM

Shaft + Sealing Plate Material: ss304 or ss316

Thermal Protection: PTC 160°C

Ex-Zone: 2

Our most powerful agitator for those tough requirements

Application: For hard to mix and higher dry matter slurry. The specially developed SUMA damping system, strengthened sealing plate and strengthened propeller make the AMT the Giantmix AMT 3 and 5 are perfect solutions.

Installation Depth: Installation of up to 6.0m beneath liquid level.

Damping System: Unique rubber on cylinder wall bracket and in hinged brackets.

Drive Transmission: helical gear, two-step spur gear for low-noise operation.

Propeller Diameter: 1,000 – 1,200mm

Easy Maintenance: Almost all maintenance activities can be carried out from outside the tank, meaning less downtime, and less operator risk.

Giantmix AMT Long Axis

Vertically Adjustable: +/- 30°

Horizontally Adjustment: +/- 20°

Electric Motor: 11.0 – 28.0 kW (50Hz)

Shaft Length: 4.0 – 6.5 m

Propeller: Ø720 – 1,200 mm

Propeller Speed: 135 RPM

Shaft + Sealing Plate Material: ss304 or ss316

Thermal Protection: PTC 160°C

Ex-Zone: 2

High performance mixer for high dry matter content

Application: For hard to mix and higher dry matter slurry.

Installation Depth: Installation of up to 6.0m beneath liquid level.

Drive Transmission: Helical gear, two-step spur gear for low-noise operation.

Easy Maintenance: Almost all maintenance activities can be carried out from outside the tank, meaning less downtime, and less operator risk.

Giantmix AMX

Vertically Adjustable: +5°/- 30°

Horizontally Adjustable: Pre-set 25°

Electric Motor: 15.0 – 22.0 kW (50Hz)

Shaft Length: 4.0 – 6.0 m

Propeller Speed: 82 RPM

Thermal Protection: PTC 160°C

Ex-Zone: 3

Coming soon!

Get in touch with our friendly staff below

Get in touch today to see how we can make your waste work.